Building productivity with robots and cobots

Volker Spanier at Epson EMEA argues that the UK and Europe need more automation in the workplace

Robots have come a long way since their first introduction onto the assembly lines in the automotive and manufacturing industries. Once confined to repetitive or dangerous tasks, developments in robotics, software and mobility are enabling today’s new breed of machines to work alongside humans in a growing number of diverse roles.

From mobile phone production and testing, to warehouse logistics and micro fulfilment, robots are also on the move in a variety of different environments. Even sorting newly harvested vegetables and carefully picking asparagus! They are taking on an array of jobs that formerly relied on human thinking, dexterity, and mobility.

Such advancements are bringing about a new era of automation, with robots poised to become collaborative partners to humans, enhancing productivity across many jobs and improving manufacturing performance. What’s more, these machines are becoming easier to reprogram and redeploy, providing much needed flexibility.

The road to reincarnation

Historically, industrial robots on production lines were complicated to reconfigure, but could last for twenty years or more. Ideal for industries like automotive, perhaps only requiring three iterations to accommodate new models during their lifetime. They were, and remain, dependent on specialist technical skill sets to maintain, often needing expensive peripheral equipment and complex software programs to manage their processes.

Whereas, modern robots are getting simpler to program and require far less technical expertise to repurpose for new products and processes. This is reducing the need for additional equipment and highly qualified staff. And, with accurate, sensitive sensors, whether on wheels or walking, these machines are more mobile and transportable than ever before.

At the moment, repurposing robots is still limited to fairly basic applications for straightforward tasks. But, it’s time to stop thinking of them as one-trick ponies. Robots should be viewed as multi-functional companions - cobots - able to be reincarnated and re-skilled. The time is coming when they will be repurposed multiple times, especially in the rapidly changing world of consumer goods where trends come and go quickly.

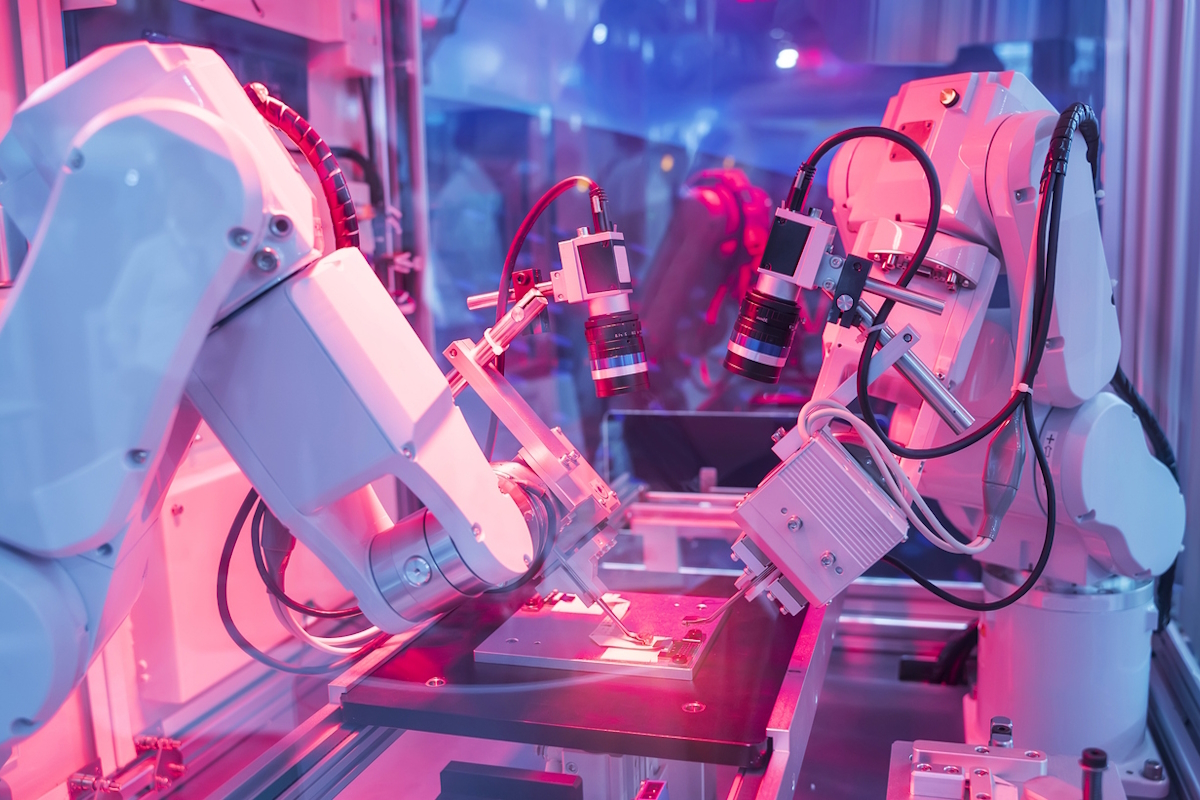

Today, consumers want to upgrade to the latest gadgets as soon as they become available, with manufacturers striving to innovate more quickly than their competitors. The mobile phone industry is already setting the pace in consumer robotics, turning outdated phones into shiny new models as frequently as every six months. Cobots are working with humans to revolutionise mobile device manufacturing - improving efficiency, accuracy, and speed, and keeping the production lines rolling.

Refurbishment made easy

When it comes to repurposing robots, companies like Epson are already offering Industrial Automation Software which requires little or no coding ability to program. In a visual-based teaching environment designed for users who are new to robot automation, an intuitive, visual user interface makes it easy to get started quickly, managing key functions like jogging, gripper control and motion. The application provides the power and flexibility of a scripted-text programming language with a simple-to-follow, block-style format. Included are standard application templates for common tasks like, pick-and-place, palletising and depalletising applications with ready-to-use template programs and tutorials.

This means customers can now take control of refurbishing their robots for a growing number of tasks. While not forgetting the legal obligations around safety that require close attention and must be followed to the letter. No-one wants to build unsafe products or face having to organise mass recalls and reconfiguring of non-compliant stock. That said, there’s no doubt reprogrammable robots for increasingly sophisticated applications are on their way, and in the not-too-distant-future.

Robotics-as-a-Service on the horizon

Also on the horizon is the concept of robotics-as-a-service. Why plan to invest in thousands of robots, if you don’t need them working all day, every day, year after year? According to recent research, the Robotics-as-a-Service (RaaS) market is expected to reach 6.2 billion dollars by 2032.

While established manufacturing industries have taken a capex approach to equipment, their modern counterparts often want more flexibility and think in opex terms. Although, capex is logical for the automotive industry where models last for 5 to 10 years, consumer goods such as laptops or IoT devices are more likely to require alternative financing as new models change quickly and demand fluctuates over 1 to 2 years. Or perhaps a hybrid set up would be more fitting. Either leased or rented to deal with initial early demand, along with purchasing some equipment for ongoing fulfilment.

Robots are getting greener

Refurbishing robots and as-a-service options also make sense for the environment. As a further step, robots which have built products could disassemble them as well. Take the case of an electric car, where robots sort materials into sections and components on vehicle production lines for assembly. There’s no reason why they shouldn’t do the same for recycling. Of course, extracting components such as lithium batteries safely will require co-ordinated, careful handling by multiple robots, but the logistics are already being investigated by researchers. And it is only a matter of time before robots are routinely identifying and separating all kinds of materials and components, selecting what can be repurposed, how items should be handled, and passing them on to the next cohort of robots for further treatment.

Moreover, with the EU legislation tightening around the circular economy, it probably won’t be long before manufacturers are obliged to show how new products can be recycled as part of safety and green compliance. Effectively, this transparency would make it easier for other organisations to identify, recycle, repair, or repurpose items made by other manufacturers and competitors, leading to less waste and obsolescence.

Robotics modernisation is accelerating

Modern robots, especially those designed to be sustainable and repurposable, represent a powerful tool for growing the UK economy. By automating tedious and physically demanding tasks, robots can address labour shortages and improve productivity.

It’s understandable for people to feel anxious about such transformative technologies - after all, robots are an unfamiliar addition to most workplaces. Therefore, it’s essential to address concerns sensitively. However, the past shows that innovation is usually disruptive, but often leads to new industries, jobs, and opportunities.

Robots will complement employees, not replace them, taking on repetitive or hazardous roles so humans can focus on more creative and strategic activities. Rather than fearing robots, it’s important to recognise their potential for a more sustainable and prosperous future. Otherwise, the UK and Europe will get left behind as the modern robotics industry continues to accelerate. Countries, such as China, are already investing in a new generation of robots, and it’s time for the rest of us to catch up.

Volker Spanier is Head of Manufacturing Solutions at Epson EMEA

Main image courtesy of iStockPhoto.com and kynny

Business Reporter Team

You may also like

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543