Driving next-level efficiency in the chemical industry

Sponsored by ABBMeet the electric motors set to bring the highest levels of energy efficiency to hazardous areas

Chemicals are the carbon-heavy lifeblood of global industry, and motors are the beating heart that drives their production. They power pumps, fans, compressors and many other applications. Across industry, pumping systems consume a significant amount of electricity, accounting for 10 per cent of the world’s total electrical energy consumption and approximately 20 per cent of industrial electricity usage.

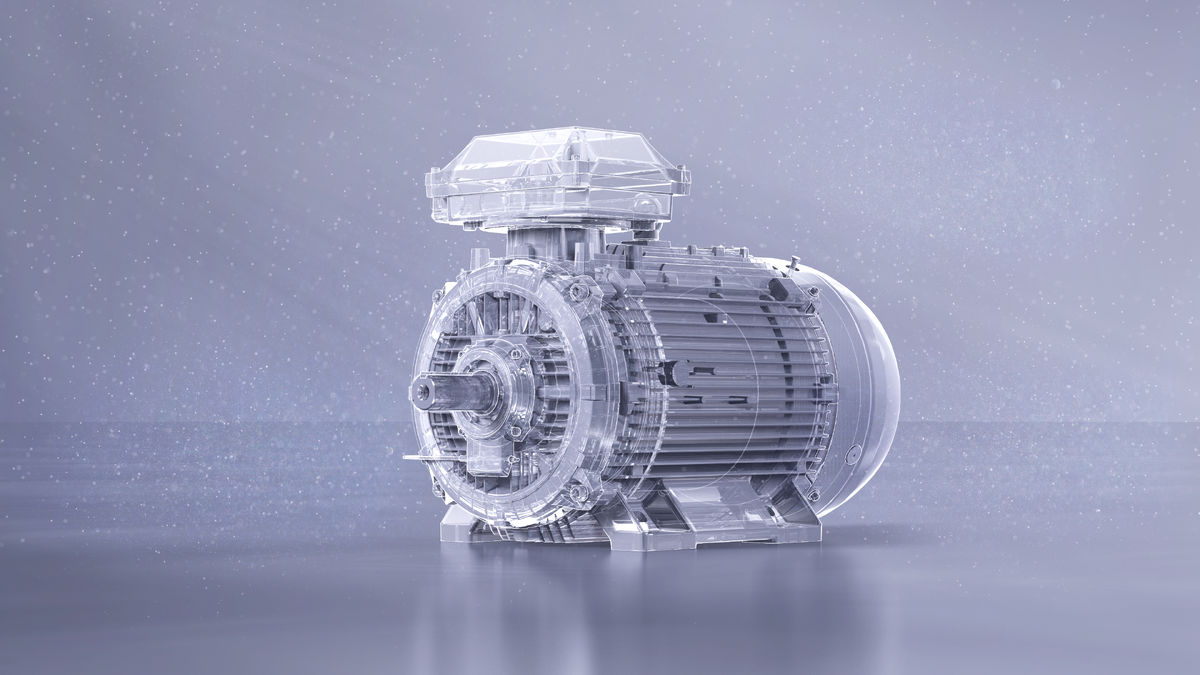

To address the climate emergency, business leaders need to find new and better ways to power the chemical industry – without compromising on cost or performance. Right on cue and purpose-built for the challenge, ABB’s SynRM Increased Safety motors secure energy savings, reduced emissions and a brighter future for our planet.

Change is essential

A paramount global concern for the chemical industry is to improve its energy efficiency. The reason is that according to the International Energy Agency (IEA), this sector ranks as the second-largest consumer of industrial energy and is the third-largest direct emitter of CO2. The potential for progress is evident, as technology already exists to make substantial strides towards achieving carbon neutrality within decades. Key to this journey is the replacement of outdated equipment with newer, energy-efficient alternatives.

The nexus of efficiency: drives and motors

Considering the chemical industry’s energy-intensive nature and its escalating demands, the role of motors and variable speed drives (VSD) becomes critical. ABB’s award-winning synchronous reluctance (SynRM) motor and drive packages eclipse the alternatives in achieving the highest levels of efficiency (IE5) currently attainable. The extension of the range to include the new SynRM Increased Safety motors unlocks new levels of energy efficiency within extreme environments.

Economic benefits and the total cost of ownership

The imperative to enhance energy efficiency in chemical production processes is a pivotal stride towards a sustainable future. With SynRM Increased Safety motors, customers operating in hazardous area industries where explosive gas, vapour or dust might be present can ensure safety and boost their energy efficiency. These motors have up to 40 per cent lower energy losses compared to commonly used IE3 motors, helping businesses save energy and boost productivity. Using SynRM technology can lead to substantial reductions in electricity consumption within motor-driven systems – often by 25 per cent or more. Furthermore, SynRM motors tend to run cooler, ensuring a longer life with lower maintenance needs.

While less efficient motors might have lower initial capital expenditures (CapEx), assessing the total cost of ownership (TCO) reveals the true story. Around 97 per cent of a SynRM motor’s TCO arises from the electricity it uses throughout its service life, with maintenance comprising just 1 per cent and CapEx only 2 per cent.

Case in point: savings in action

A compelling case story exemplifies the potential of SynRM motors. The world’s largest nitrogen-based complex fertiliser producer has partnered with ABB to enhance energy efficiency through the replacement of thousands of outdated motors. The long-term upgrade project will yield annual energy savings of up to 40 gigawatt hours (GWh) and cut CO2 emissions by 19 kilotons (kt) – equivalent to the emissions produced by nearly 14,000 standard cars.

The urge for change

Significant changes in the way we supply and use energy are required to prevent the worst outcomes of climate change. Amid escalating product demand, the chemical industry is generally highly energy-intensive. This calls for urgent implementation of energy efficiency solutions. The good news is that solutions such as high efficiency motors and VSDs are already well-proven and commercially available across all industries. Our two challenges are to identify where they can make the greatest difference and to encourage their uptake. This will pave the way towards achieving Net Zero without an increase in net cost.

For more information about the energy efficiency opportunities in the chemical industry, read our whitepaper

By Stefan Floeck, Division President IEV Low Voltage Motors, ABB Motion

Business Reporter Team

You may also like

Related Articles

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543